How To Test Your Golf Cart Motor For A Short

It’s a good idea to test your motor before installing a new controller. A motor with a short could have damaged the original controller and the new one.

IMPORTANT: These tests will not show if there is a short in the armature. That test requires a special tool that only motor repair facilities have. Your motor could test OK with the methods below and still have a short. Below are just some simple test that may indicate a possible problem. For a comprehensive test you will need to take your motor to a repair facility.

You will be testing for continuity, which basically means you are testing for an electric connection between two points. If you are unfamiliar with continuity tests here is a good website that show the basics of setting up many different meter types (scroll down the page).

Note that continuity is non-directional. It does not matter which color leads from your multimeter are on which post of the motor.

Also, keep your fingers from touching the metal leads on the meter or it will mess up your readings.

Set your multimeter to the continuity check setting if it has one, or to the ohms setting. The continuity setting is normally a little wave symbol (like a wifi symbol). The Ohms setting (Omega) looks like a little horseshoe. Sometimes they are on the same setting. In the continuity check mode most meters will beep when there is continuity. You can cross your leads tips to check.

When crossing your leads in the ohms setting mode it will likely show a tiny amount of resistance inherent in the tester, but should be close to zero.

Now do the following tests.

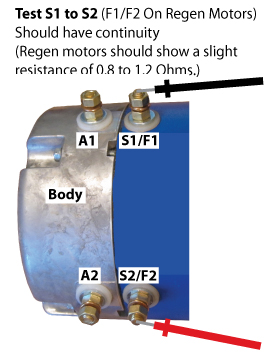

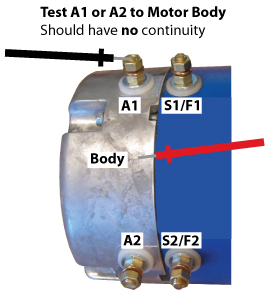

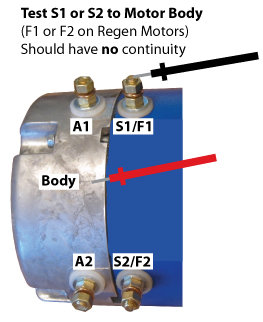

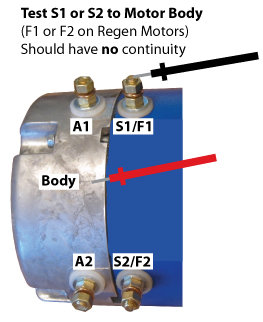

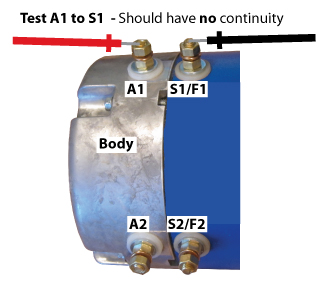

There should be continuity between A1 & A2, and between S1 & S2 (F1 & F2 on a regen motor). You should have no continuity from A1 to the motor body, or S1(F1) to the motor body, or between A1 and S1 (F1).